- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

42CrMo Alloy Steel Casting

42CrMo Alloy Steel Casting is often used to manufacture high-strength mechanical parts, such as gears, shafts, bolts, nuts, hydraulic cylinders, cylinders, pins, engine parts, etc.

Send Inquiry

Material: 42CrMo Alloy Steel Casting

Product name: L01 connector

Process: silica sol precision casting

Gross weight: 0.197

Application: engineering machinery

Surface treatment: anti-rust water

The product requires heat treatment and machining

Material: 42CrMo

Product name: 2 connectors

Process: silica sol precision casting

Gross weight: 0.053

Application: engineering machinery

Surface treatment: anti-rust water

The product requires heat treatment and machining

Material: 42CrMo

Product name: 708 connector

Process: silica sol precision casting

Gross weight: 0.123

Wax: medium temperature wax

Application: construction machinery

Surface treatment: anti-rust water

Product requires heat treatment and machining

Material: 42CrMo

Product name: P070P connector

Process: Silica sol precision casting

Gross weight: 0.898

Wax: Medium temperature wax

Application: Engineering machinery

Surface treatment: Anti-rust water

The product requires heat treatment and machining

Silica Sol Product Characteristics

|

Process |

Investment Casting (Green Wax) |

|

Mold |

General Aluminum Mold & Steel Mold |

|

Mold Material |

Middle Temperature Wax |

|

Mold Shell |

Silica sol, Mullite Sand, Zircon Sand |

|

Technology Characteristics |

Suitable for producing small parts. Better precision. Better surface roughness. Can large extent reduce machining. |

|

Tolerance Range |

CT5 to CT6 |

|

Single Weight |

0.01kgs to 30kgs |

|

Surface Roughness |

RA6.3 |

|

Casting Material Type |

Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron. |

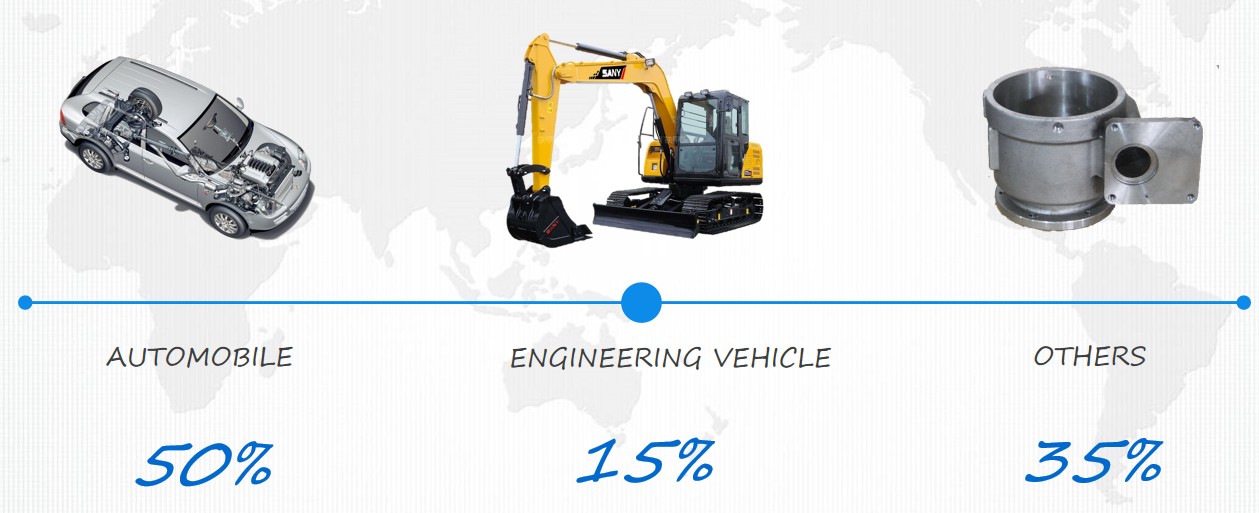

Product application area ratio

Main customers:

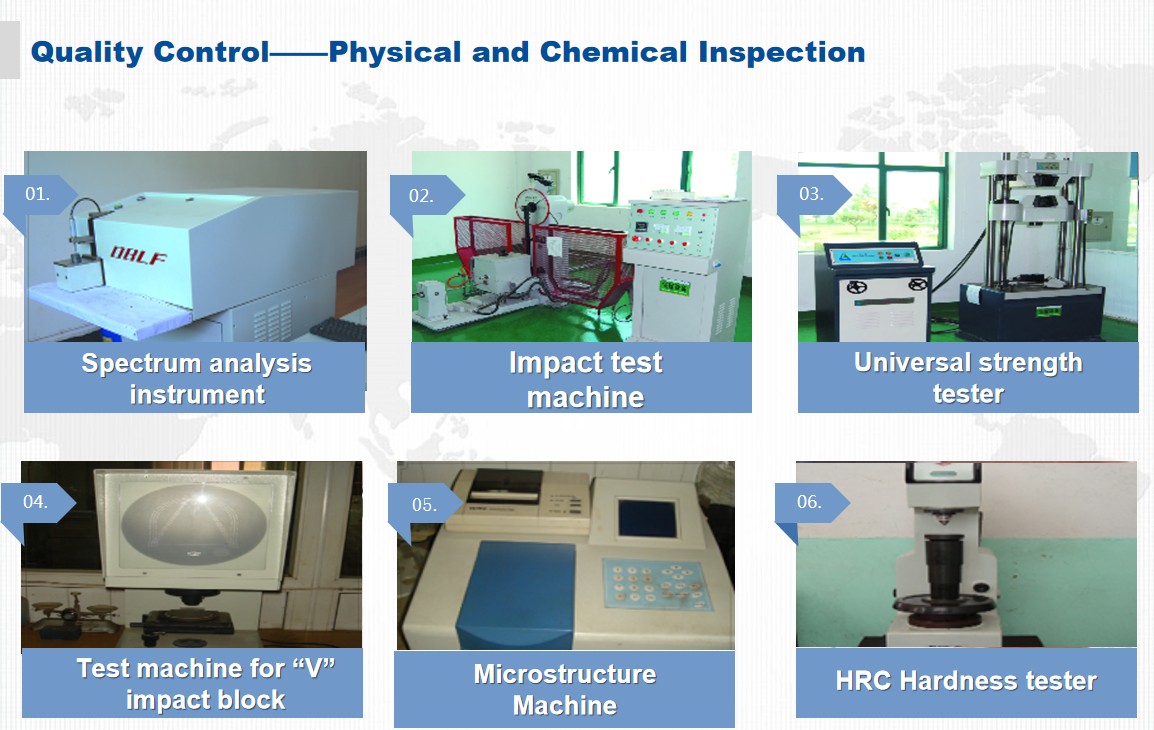

Quality Control