- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

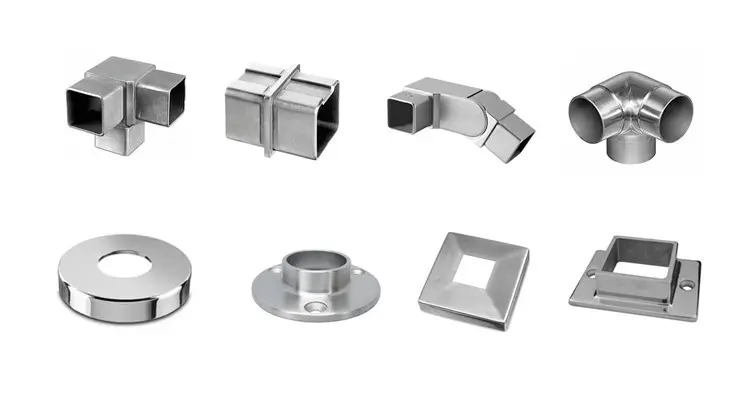

Experts Level Casting News

10 Reasons you should choose Ningbo Zhiye for investment castings

Investment castings made in China is already a big trends for global companies. Tongda has been supplying investment castings from various industries for many years and always win good reputation from our customers.Today we would like to talk about 10 reasons you should choose Tongda for investment ......

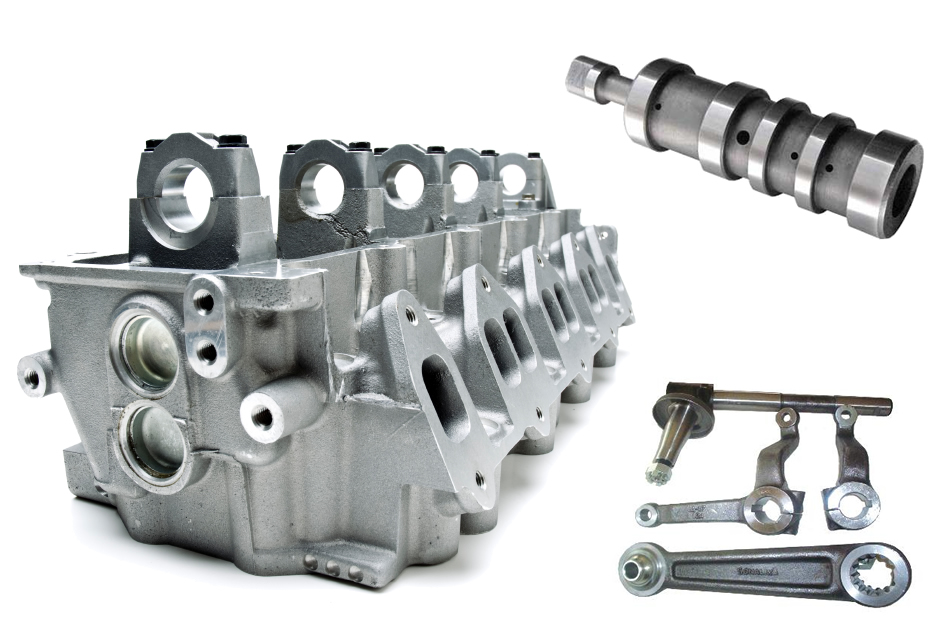

Read MoreCategories of cast irons in Ningbo Zhiye Mechanical Components Co.,Ltd.

Cast iron is iron carbon alloy which carbon content is greater than 2%.Carbon exist in cast iron mostly as graphite morphology,sometimes as cementite. In addition to carbon,also contains 1%~3% of silicon in cast iron,and manganese,phosphorus,sulfur and other elements..Cast iron could be divided into......

Read MoreDesign the structure of the gray iron investment castings

We usually should pay attention to the following factors when designing the structure of gray iron investment castings: *The wall thickness should be not too thin and we may add the thickness in the corners of gray iron investment casting.To prevent chilling organization become hard and brittle......

Read MoreWhat are the Factors affect surface roughness of investment castings?

The surface of investment castings would be oxidized for high temperature during metal liquid pouring and solidification process.As the oxide layer is uneven and metal oxide on the casting surface would have effect on oxide in shell.Prompting uneven falling from of investment casting surface,which w......

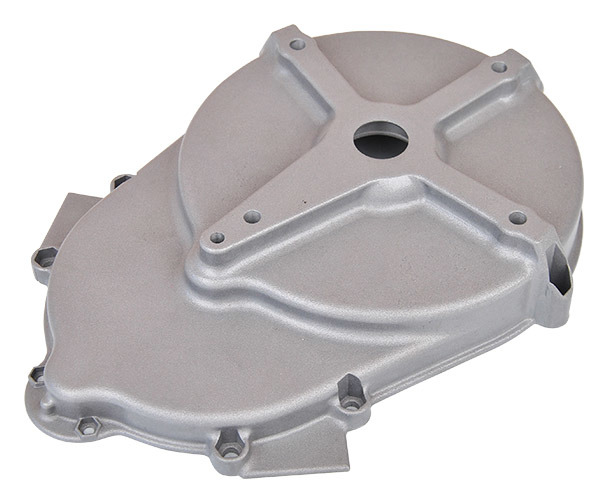

Read MoreCompostion of die casting aluminum in Ningbo Zhiye Mechanical Components Co.,Ltd.

The pure aluminum can only be used into cables,heat exchange system and capacitors since there is no high requirement for low load,low corrosion resistance and electric conduct in these field.By compare to pure aluminum,aluminum alloy can be widely used in many field.By adding certain elements into ......

Read More