- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

QT500-7 Ductile Iron

QT500-7 ductile iron is a mixed matrix ductile iron. With its excellent mechanical properties and wide applicability, it plays an important role in many fields. It is used in hydraulic valve blocks, distributors, cylinder heads, guide sleeves, gear pump gears, machine tool guide rails, gear pump gears, machine tool guide rails, flywheels, bearing seats, chucks, etc.

Send Inquiry

Material: QT500-7

Product Name: 50T Nut

Process: Lost Foam Casting

Gross Weight: 2.3mm

Foam Forming

Application: Construction Machinery

Surface Treatment: Rust-Proofing Water

Product Requires Heat Treatment

Material: QT500-7

Product Name: Connector

Process: Lost Foam Casting

Gross Weight: 0.933

Foam Molding

Application: Construction Machinery

Surface Treatment: Rust-Proofing Water

Product Requires Heat Treatment

Material: QT500-7

Product Name: Connector

Process: Lost Foam Casting

Gross Weight: 0.231 in, 0.321 in, 1.17 in

Foam Molding

Application: Construction Machinery

Surface Treatment: Rust-Proofing Water

Product Requires Heat Treatment

Material: QT500-7

Product Name: Counterweight

Process: Silica Sol Precision Casting

Gross Weight: 0.099

Medium Temperature Wax

Application: Construction Machinery

Surface Treatment: Galvanized

Product Requires Heat Treatment

Silica Sol Product Characteristics

|

Process |

Investment Casting (Green Wax) |

|

Mold |

General Aluminum Mold & Steel Mold |

|

Mold Material |

Middle Temperature Wax |

|

Mold Shell |

Silica sol, Mullite Sand, Zircon Sand |

|

Technology Characteristics |

Suitable for producing small parts. Better precision. Better surface roughness. Can large extent reduce machining. |

|

Tolerance Range |

CT5 to CT6 |

|

Single Weight |

0.01kgs to 30kgs |

|

Surface Roughness |

RA6.3 |

|

Casting Material Type |

Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron. |

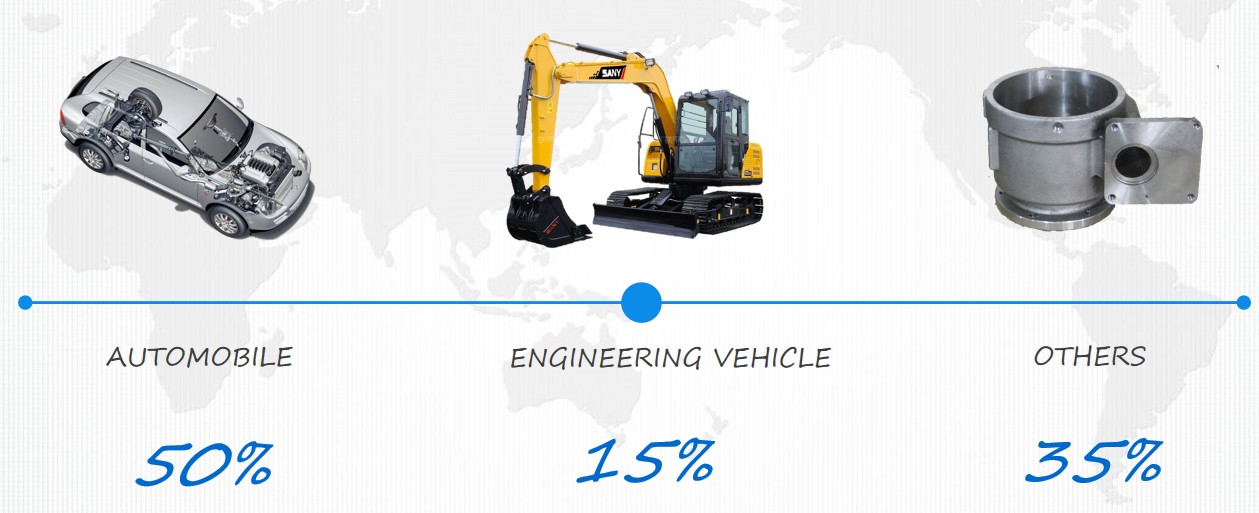

Silica Sol Precision Casting Joint application area ratio

Main customers:

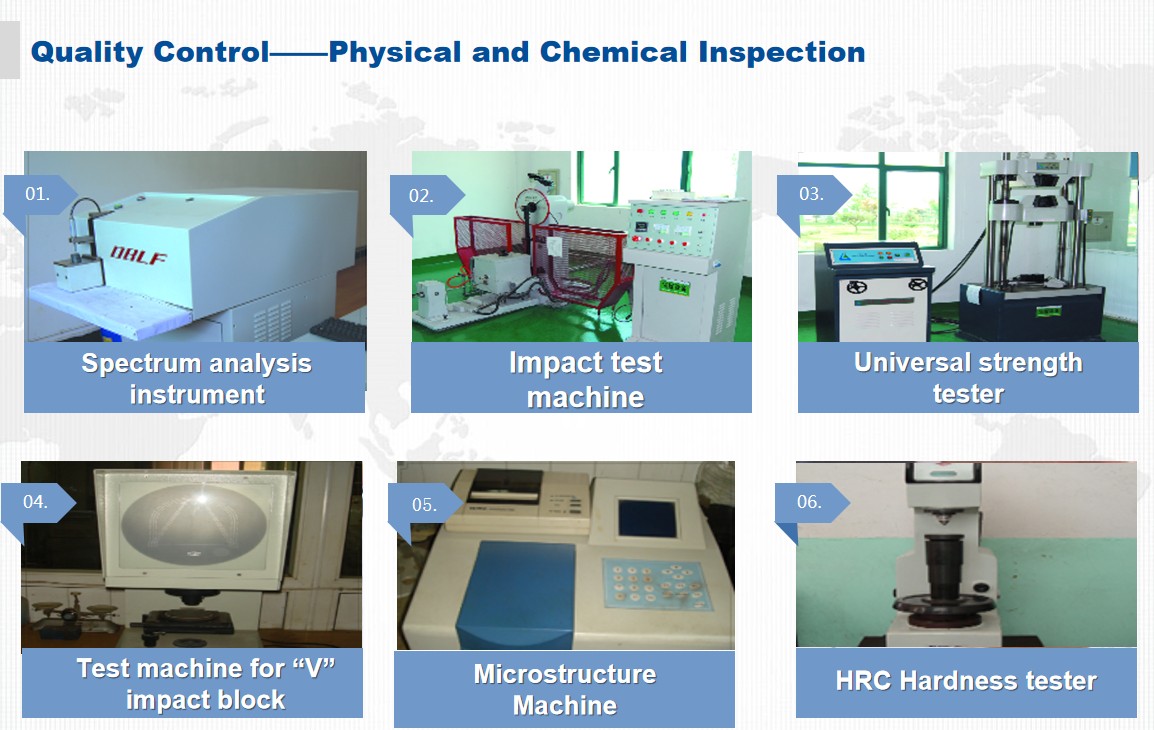

Quality Control