- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

QT600-3 Ductile Iron

QT600-3 is a pearlitic ductile iron with medium-to-high strength, medium toughness and plasticity, high comprehensive performance, good wear resistance and vibration damping, and good casting process performance. It is used in various power machinery crankshafts, camshafts, connecting shafts, connecting rods, gears, clutch plates, hydraulic cylinders, camshafts, connecting shafts, connecting rods, rocker arms, etc.

Send Inquiry

QT600-3 is a pearlitic ductile iron with medium-to-high strength, medium toughness and plasticity, high comprehensive performance, good wear resistance and vibration damping, and good casting process performance. It is used in various power machinery crankshafts, camshafts, connecting shafts, connecting rods, gears, clutch plates, hydraulic cylinders, camshafts, connecting shafts, connecting rods, rocker arms, etc.

Material: QT600-3

Product Name: Stator Impeller

Process: Silica Sol Precision Casting

Gross Weight: 2.0 kg

Wax: Medium Temperature Wax

Application: Construction Machinery

Surface Treatment: Rust-Proofing Water

Product Requires Heat Treatment

Silica Sol Product Characteristics

|

Process |

Investment Casting (Green Wax) |

|

Mold |

General Aluminum Mold & Steel Mold |

|

Mold Material |

Middle Temperature Wax |

|

Mold Shell |

Silica sol, Mullite Sand, Zircon Sand |

|

Technology Characteristics |

Suitable for producing small parts. Better precision. Better surface roughness. Can large extent reduce machining. |

|

Tolerance Range |

CT5 to CT6 |

|

Single Weight |

0.01kgs to 30kgs |

|

Surface Roughness |

RA6.3 |

|

Casting Material Type |

Carbon Steel, Alloy Steel, Stainless Steel, Ductile Iron. |

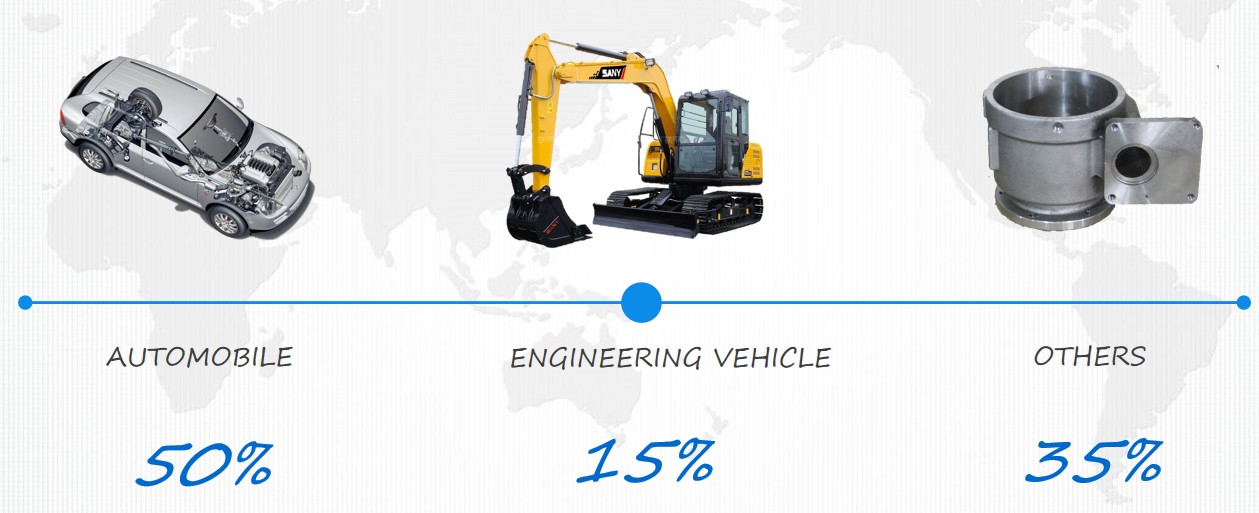

Silica Sol Precision Casting Joint application area ratio

Main customers:

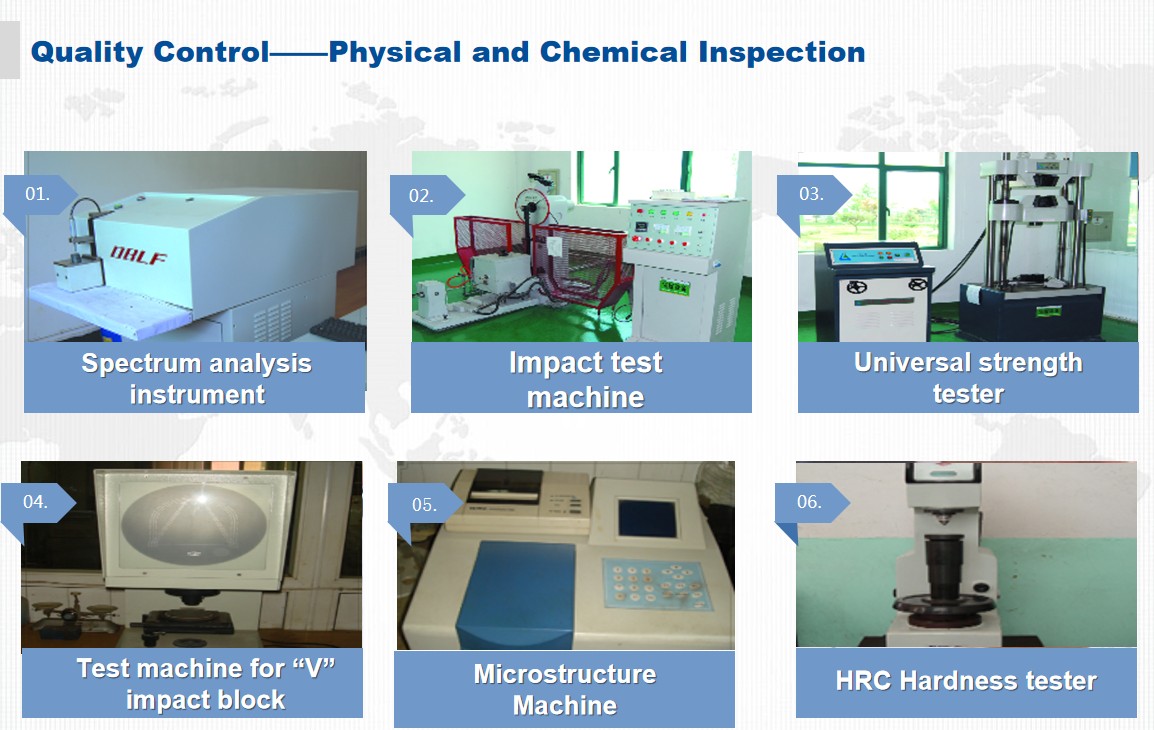

Quality Control