- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

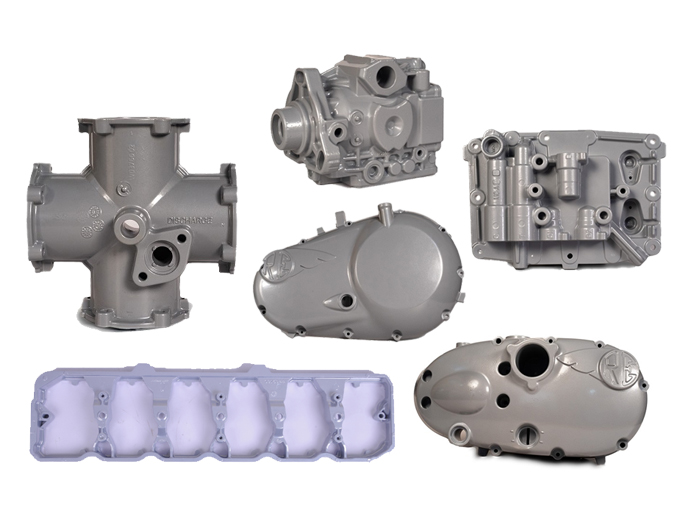

Different Shot blasting for aluminum die castings

With the development of automobile, machinery, aerospace, instrumentation and other industries,the application of aluminum die castings are gradually expanded.Meanwhile,aluminum die casting purchasers also put forward higher requirement on the surface quality.Now we would like to introduce shot blas......

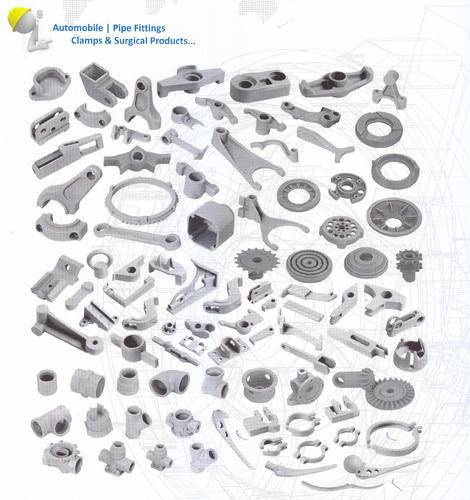

Read MoreHow could we deal with the surface cleaning for investment castings?

Ningbo Zhiye is a technical investment casting foundry producing various precision investment castings.By professional investment casting production equipment,strong techincs,strict quality control system and impeccable testing equipments,we have win great trust and support from investment casting ......

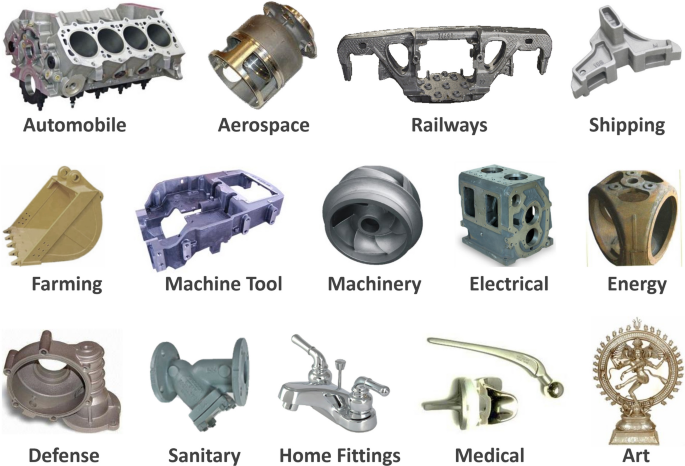

Read MoreHigh Pressure Die Casting VS Lost Foam Casting

High pressure die casting and lost foam casting are both casting methods which widely used in automobile industry,telecommunication industry,medical industry etc.Both of casting methods can produce parts with complex geometry shape at tight tolerance requirement.But they are typically used for some ......

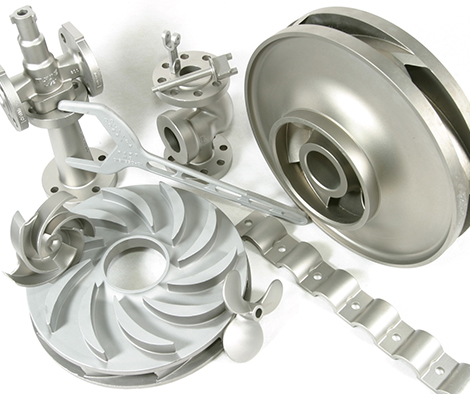

Read MoreDifferent mode of Inspections on Investment castings?

We will test the material to analyze the chemical components of the cast materials. Thus, to ensure the percentages of all elements are within the required range. The material inspection will be done before casting and after casting. Two processes are mainly used to test the chemical components of m......

Read More